The reverse rotary table is perfect for using on the tilting angle table (P/N 3750).

#Sherline rotary table deskcnc manual

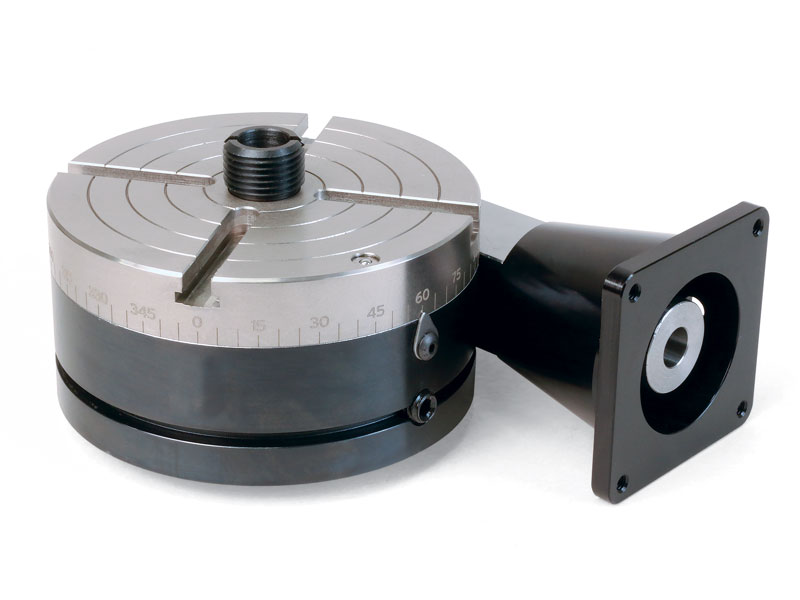

Its P/N 3700-OP manual 4" rotary table and applied a stepper motor mount with P/N 3700-OP (manual) mounted to an optional P/N 3750 Tilting Angle Table (Click on image for a larger view). Reverse Rotary Table with Stepper Motor Mount. Includes hold-down clamps, T-nuts, and screws to hold the rotary table to the mill table, and a 3/8-16 to 3/4 x 16 chuck adapter to hold a chuck directly to the rotary tableĬNC-ready machines cannot be operated manually until stepper motors are.This allows the table to be used as a 4thĪxis with CNC systems that have the capability to drive a rotary axis. Its P/N 3700 manual 4" rotary table and applied a stepper motor mount withĭampened coupling in place of the handwheel. Rotary Table with Stepper Motor Mount (Click on image for a larger view). This will allow the maximum diameter of stock to feed through the rotary table (See Figure 2). In order to use this rotary table with our Tilting Angle Table (P/N 3750) you will need to drill out the 10-32 center hole to 1/2″ diameter. Includes hold-down clamps, T-nuts, and screws to hold the rotary table to.6485" c’bore at the entrance of the 5/8-24 thread which is used to locate the adapter concentric to the rotary table The chuck adapter (P/N 37097) has a 3/4-16 thread for the chuck and a 5/8-24 thread for the rotary table.The through hole on this rotary table is 15/32" (.469").They wanted a rotary table that had a larger through hole to which you could mount our chucks. This modification came about after requests from our laser engraving customers. This is a modification of our P/N 3700 4" Manual Rotary Table. (Click on images for a larger view).Ĥ" Nickel-Teflon Coated Manual Rotary Table w/ 15/32" Through Hole The CNC-ready version and chuck are shown for reference only theĬhuck is not included. Right is the P/N 3710-CNC Rotary Table with a chuck in place to show the NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table. Includes hold-down clamps, T-nuts, and screws to hold the rotary table to the mill table, and a 3/8-16 to 3/4 x 16 chuck adapter to hold a chuck directly to the rotary table.Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Ball bearings are shown in dark blue (Click on images for a larger view). The 3D rendering on the right is a ghost view of the rotary table, drawn in SolidEdge® by John Costello, shows the internal mechanism so you can see how the worm gear drives the table. Laser Marking Systems who use a high-speed motor to drive the table. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. Its compact size makes it a good fit in small enclosures. Sherline’s rotary table offers an accurate, stable platform for rotary laser marking applications. The rotary tables can hold more weight when they are not under a continual load. weight when suspended 12" away from the center of the rotary table)

This gives the table a rust resistant surface that is hard and has added lubrication qualities. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. The larger through hole allows for larger stock to be held. The rotary table also is available with larger, 15/32" through hole to which youĬan mount our chucks. It's popular among industrial shops due to its compact size, solid construction, It can even be purchased with its one controller to be used as a programmable indexer. It is available in manual or stepper motor drive modes. Sherline offers one of the finest small rotary tables on the market. Programming is simple and controls speed, direction, and Rotary table is driven by a NEMA 23 stepper motor controlled by input at the Rotary Table w/ Nickel Plated Coating w/ Stepper Motor and Controller. The only limits are size, not complexity. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines, however, it can be used on any mill whenever the small 4-inch size would be an advantage. A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design.

0 kommentar(er)

0 kommentar(er)